| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | LIANZHONG |

| Model Number : | 1000series, 2000series, 3000series, 5000series, 6000series, 7000series |

| Certification : | ISO9001 |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T, Western Union |

| Supply Ability : | 20000 Ton/Tons per Month |

| Delivery Time : | 15-21 days |

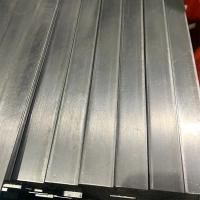

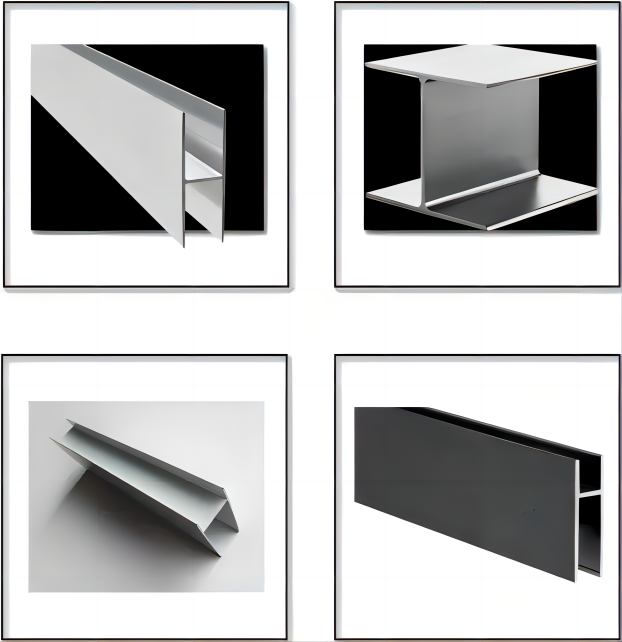

ASTM 6082 Silver Aluminium H Beam 8mm Thickness Used For Aluminium Formwork Panel For Construction

H-beam steel can be produced by welding or rolling. H-beam welding is done by cutting strips of suitable thickness to suitable widths and welding flange and web together in a continuous welding set. The welding H beam has some disadvantages such as large metal consumption, not easy to ensure uniform product performance and limited size. Therefore, H - beam is mainly produced by rolling method. In the modern rolling production, the universal mill is used to roll H - beam steel. The web of H-beam is rolled between the upper and lower horizontal rolls, and the flange is rolled simultaneously between the side of the horizontal roll and the vertical roll. Since the flange end cannot be pressed with only universal rolling mill, it is necessary to set the edge rolling machine, commonly known as edge rolling machine, behind the universal frame in order to press the flange end feeder and control the flange width. In the actual rolling operation, the two stands are taken as a group to make the rolling parts reciprocate for several times, or to make the rolling parts pass through the continuous rolling unit composed of several universal stands and one or two edge end stands. Each pass applies a certain amount of pressure to roll the blank into the product of the required specification shape and size. At the flange of the rolling part, the wear of the roll is relatively large because of the sliding between the horizontal roll side and the rolling part. In order to ensure that the roll can be restored to its original shape after heavy rolling, the sides of the upper and lower horizontal rolls and the corresponding vertical roll surfaces of the roughing mill should be 3. ~ 8. The dip Angle of theta. In order to correct the dip Angle of the finished flange, the finished universal rolling mill, also known as the universal finishing mill, is set. The horizontal roll side is perpendicular to the horizontal roll line or has a small inclination Angle, generally no more than 20', and the vertical roll is cylindrical.

Product | aluminum H beams |

Alloy | 6063,6061,6082 |

Temper | T5,T6 |

Thickness | 0.4mm-500mm |

Size | 0.5 m to 11.85 m, non-standard: custom-made |

Tolerance | +/-0.1mm |

Shape | Rectangular, customized. |

Standard | EN 755 - 9, GB/T 6892-2015, GB 5237.1-2008, JGJ 386-2016. |

process | Drilling, bending, welding, precise cutting, punching, etc. |

Type | Flat formwork, corner formwork, beam formwork, etc. |

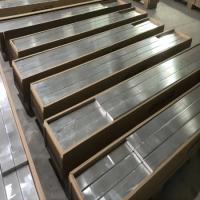

Package | Standard pallet with waterproof film, or according to your

requirement. |

Grade | Hardness | Tensile Strength | Yield Strength | Elongation(%) | |

(MPa) | (MPa) | 0.25-1.25mm | 1.26-3.0mm | ||

1100 | O | 89.6 | 34.5 | 30 | 6 |

H12 | 110.3 | 103.4 | 4 | 12 | |

H14 | 124.1 | 117.2 | 3 | 10 | |

2024 | O | 186.2 | 75.8 | 18 | 20 |

T3 | 482.6 | 344.7 | 16 | 18 | |

T4 | 468.8 | 324.1 | 20 | 19 | |

3003 | O | 110.3 | 41.4 | 30 | 33 |

H12 | 131 | 124.1 | 9 | 11 | |

H14 | 151.7 | 144.8 | 3 | 7 | |

5052 | O | 193.1 | 89.6 | 20 | 21 |

H32 | 227.5 | 193.1 | 7 | 10 | |

H34 | 262 | 213.7 | 6 | 8 | |

5083 | O | 275.8 | 144.8 | 21 | 25 |

H32 | 282.7 | 151.7 | 20 | 21 | |

H34 | 330.9 | 255.1 | 11 | 14 | |

6061 | O | 124.1 | 55.2 | 25 | 26 |

T4 | 241.3 | 144.8 | 22 | 24 | |

T6 | 310.3 | 275.8 | 12 | 17 | |

7075 | O | 227.5 | 103.4 | 16 | 18 |

T6 | 572.3 | 503.3 | 11 | 12 | |

Product Details

Packing and Shippment

Certification

|